ADVERTISEMENT

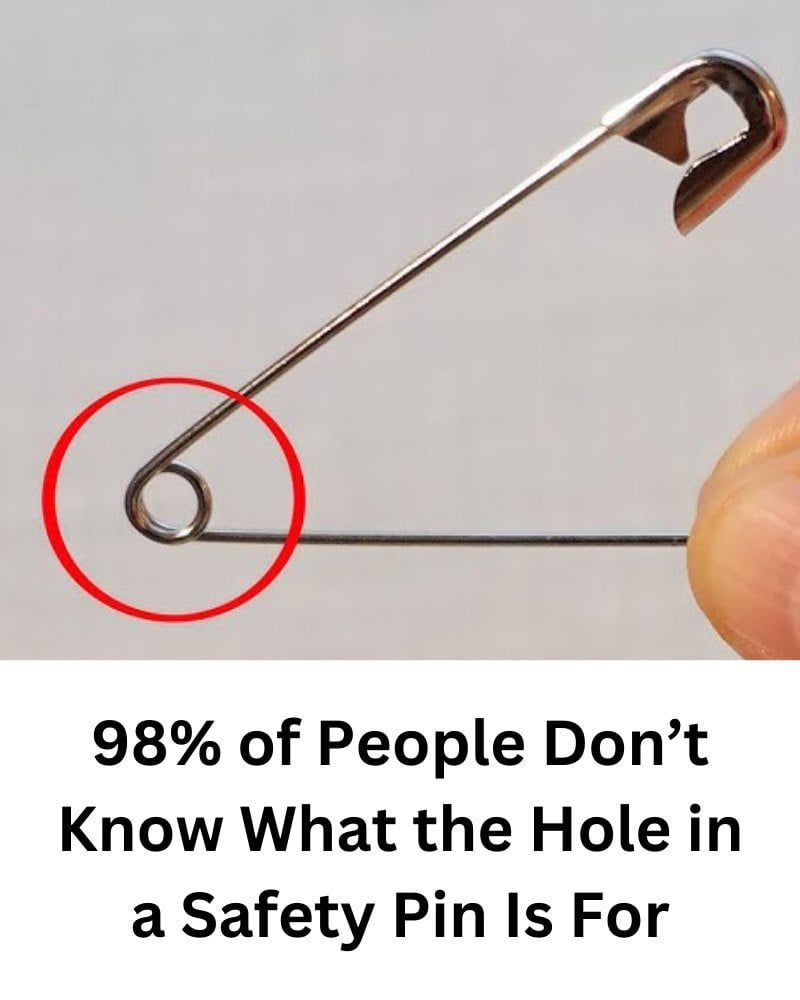

Thus, the small circle is part of a built‑in locking mechanism: it maintains pressure over the catch, keeping it closed until intentionally opened.

Compactness & Compact Form Factor

One of the challenges in designing a safety pin is to fit all this functionality — piercing, clasping, spring, safety guard — into a compact, inexpensive piece of wire. The small coil is a compact way to integrate spring action without bulky components or separate springs. It keeps the design elegant, efficient and minimal.

Early Fasteners & Predecessors

Before the safety pin, ancient civilizations used fibulae (a kind of brooch) to fasten clothing — classic in Roman, Greek and Celtic traditions. Those brooches often featured spring mechanisms, coils, and loops to allow movement and secure fastening.

In those early devices, you sometimes find curls, coils or loops incorporated into the hinge mechanism — essentially prototypes of the modern loop. These were large, ornate, and bulky, but the principles are analogous.

Over time, improvements refined that loop: making it more compact, more reliable, less prone to failure, and adjustable in size. The proportions of the loop vs. wire gauge vs. material properties matter critically. Engineers studied metal fatigue, elasticity, yield strength, and manufacturing tolerances.

As manufacturing techniques improved (better metal alloys, precise wire forming), the loop could be smaller, stronger, and more durable. That’s why older vintage safety pins often have larger or more visible loops, whereas modern ones make the loop almost invisible — yet still essential.

Continue reading…